Edwards Deming's Red Bead Experiment

To simultaneously translate English-language videos into Russian, use the new Yandex Browser feature - real-time video translation.

Source of main material: [1] - Henry R. Neave, "The Organization as a System: Edwards Deming's Principles for Building a Sustainable Business." / "The Deming Dimension. Henry R. Neave"; Per. from English - M.: Alpina Publisher, 2017. Scientific editors: Y. Adler, Y. Rubanik, V. Shper. You can purchase the book from the publisher Alpina Publisher .

Notes and illustrations: Scientific Director of the AQT Center Sergey P. Grigoryev

Free access to articles does not in any way diminish the value of the materials contained in them.

Deming began the red bead experiment in his first lectures to the Japanese in 1950 to demonstrate the difference between general and special causes of variation. For many years, Deming used the same equipment to experiment with red beads. These basic devices are: a box of white and red beads in a 4:1 ratio (3200 white and 800 red) and a rectangular spatula in which 50 vertical recesses are made. A selection of 50 beads is achieved by dipping a spatula into the box.

Video 1. Dr. Deming's Red Bead Experiment.

The basic form of the red bead experiment that was demonstrated at Deming's four-day seminars remained relatively unchanged for several years.

The master invites volunteers from the audience:

- six interested workers (they do not require any special skills: they will be trained and will have to comply with all requirements without questions or complaints);

- two junior inspectors (they only need to be able to count to twenty);

- Chief Inspector (must be able to compare two numbers to see if they are equal or not and be able to speak loudly and clearly);

- registrar (must be able to write accurately and perform simple arithmetic operations).

The workday for each worker is the process of taking a sample (50 beads) from a box using a spatula. White beads are a good product that is acceptable to consumers. Red beads are an unacceptable product. In accordance with the requirements of the master or the wishes of senior management, the task is to prevent more than one to three red beads from entering. The workers are trained by a master (Deming), who gives precise instructions on how the work should be carried out: how to mix the beads, what should be the directions, distances, angles and level of stirring when using the spatula. To minimize variations, the procedure needs to be standardized and regulated.

Workers must follow all instructions very carefully, because the results of their work determine whether they will remain at work.

"Remember, every day you work could be your last depending on how you work. I hope you enjoy your work!" - Master

The control process involves a lot of personnel, but it is very effective. Each worker brings his day's work to the first sub-inspector, who silently counts and records the number of red beads, and then goes to the second sub-inspector, who does the same. The Chief Inspector, also remaining silent, compares the two accounts. If they differ, then an error has crept in! What's even more concerning is the fact that even if both accounts agree, they may still be wrong. However, the procedure is such that in the event of an error, the inspectors, still independently of each other, must recalculate the result. When the score matches, the chief inspector announces the result and the registrar records it on a slide projected on the screen above. The worker returns his beads to the box - his work day is completed.

The work continues for four days. There are 24 results in total. The master constantly comments on them. He praises Al for reducing the number of red beads to four, and the audience applauds him. He berates Audrey for getting sixteen reds, and the audience laughs nervously. How can Audrey have four times as many defective beads unless she is careless and lazy? None of the other workers can remain calm either, because if Al could do four, then anyone can do it. Al is a definite "worker of the day" and will receive a bonus.

But the next day, nine red beads are found on Al because he has calmed down too much. Audrey brings ten: she started off poorly, but is now starting to improve, especially after her serious talk with the master at the end of the first day.

"Stop! Stop the line! Ben just made seventeen reds! Let's have a meeting and try to figure out what's causing the poor performance. This kind of performance can lead to the closure of the business." - Master

At the end of the second day, the foreman has a serious conversation with the workers. As people become more comfortable and experienced, their results should improve.

Instead, following the 54 red beads received on the first day, a whopping 65 were received on the second day. Do the workers not understand their task? The goal is to get white beads, not red ones. The future looks pretty bleak. Nobody reached the goal. They should try to do better.

Depressed workers return to work. And suddenly two glimpses appear: Audrey, continuing to improve her results, reaches seven red beads; Ben is also on the right track, repeating the success of his first day of work - nine reds! However, all others perform worse. The total number of red beads rises again and reaches 67. The day ends without success, like the previous ones. The foreman tells the workers that if significant improvements do not occur, the plant will have to close.

The fourth day begins. We are relieved to find that things have improved thanks to Audrey, who now produces only six red beads*. But overall the day ends with 58 reds, still worse than the first day.

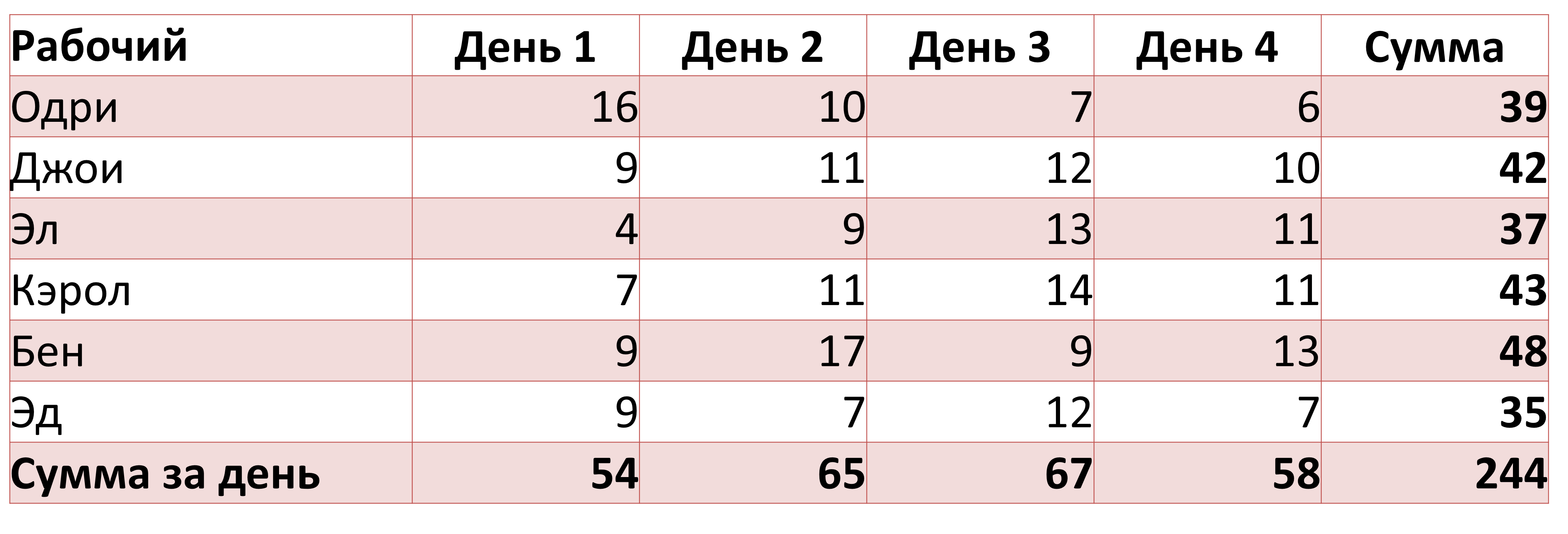

Here are all the results obtained so far:

Rice. Table of results from Deming's experiment with red beads.

At this stage, the foreman decides to call on the well-known great achievement of management for help - to save the enterprise, leaving only the best workers. He fires Ben, Carol and John, three workers who made 40 or more red beads in four days, and keeps Audrey, Al and Ed, paying them a bonus and forcing them to work double shifts.

No wonder this doesn't work.

By observing the red bead experiment, we gain a rare advantage: we understand the system well and can be confident that it is controllable. Once we realize this, it becomes clear to us how pointless it is for the master (or anyone else) to do anything to influence results that are supposedly dependent on the workers, but in fact are completely determined by the existing system. All these actions were reactions to purely random variations.

However, suppose we lack understanding of the system. What should we do then? We would then need to plot the data on a control chart and let it tell us about the behavior of the process.

Note by S. Grigoryev: To construct the control chart, Edwards Deming chose an np-chart for alternative data. But in practice, Donald Wheeler recommends using an individual value XmR reference map, both for continuous quantities (values) and for alternative data (counts).

See the article for an explanation of this recommendation.

Control charts for alternative data (counts) p-chart, np-chart, C-chart and u-chart or XmR-chart of individual values?

Literature: For rules for constructing Shewhart control charts, see GOST R 50779.42-99 (ISO 8258-91) - [11.1] Statistical methods. Shewhart control charts.

Article: Rules for determining lack of controllability according to control cards.

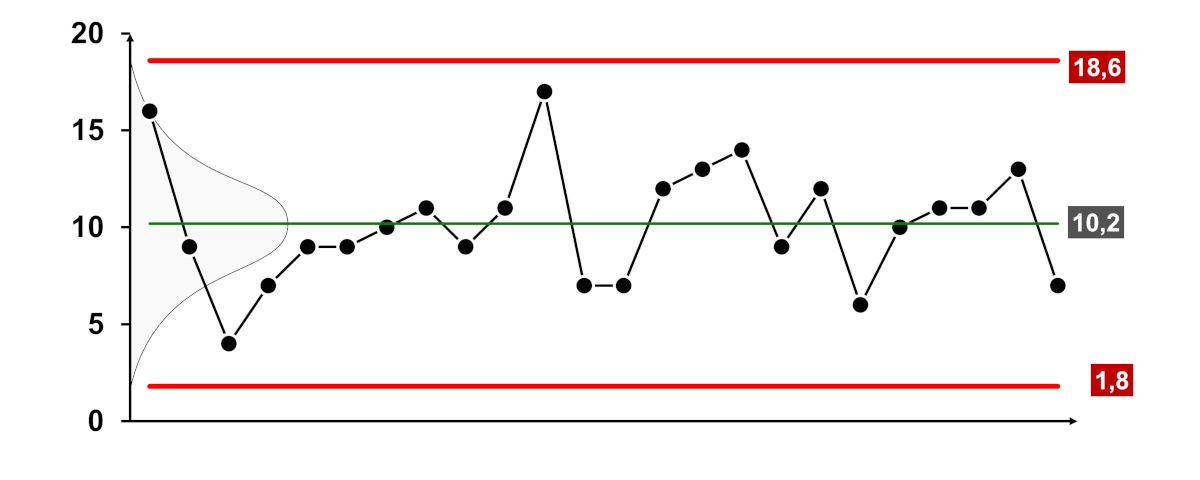

The control chart is shown in the figure below.

Rice. Control np-chart of the red bead experiment conducted by Edwards Deming in 1983.

This chart confirms what we assumed: the process is in a statistically controlled state. Variations are caused by the system. The workers are helpless: they can only give out what the system gives. The system is stable and predictable.

If we do the experiment tomorrow, or the day after tomorrow, or next week, we will likely get a similar range of results.

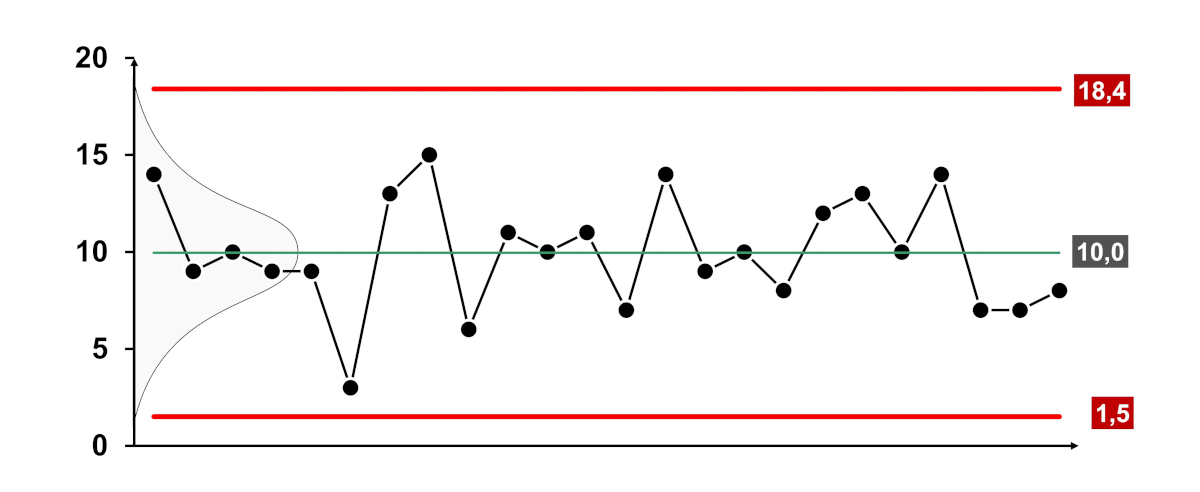

Rice. Control np-card of the experiment with red beads, conducted at a training seminar by S. P. Grigoryev in 2011.

Seminar participants see the pleasure that comes from good results and the grief from bad results, independent of the master’s curses and criticism. They see a trend (like Audrey's tendency to significantly improve her results), they see relatively uniform results (like John's), and they see variable results (like Ben's). They see and hear the master's complaints and lamentations when his useless and meaningless instructions are not followed to the letter. They see workers being compared to each other, when in reality workers have no say in producing results: results are entirely determined by the system within which they work. And the seminar participants also see how workers lose their jobs without any fault on their part, while others receive bonuses without having any special merit (except that the system treats them more loyally).

Deming points out some obvious features of the experiment plus a few others that are less obvious. Thus, the accumulated average values at the end of each of the four days are respectively:

Rice. Cumulative averages at the end of each of the four days of Edwards Deming's 1983 red bead experiment.

Deming asks the audience what value the average will settle at if the experiment continues. Since the ratio of white to red beads is 4:1, it is clear to those familiar with the laws of mathematics that the answer must be 10.0. But this turns out not to be the case. This would be correct if the sampling was carried out using the random number method. But in reality it is carried out by immersing the blade in the box. This is a mechanical sampling, not a random one, for which mathematical laws apply. As further evidence, Deming cites results obtained by using four different blades over a number of years. For at least two of these, a traditional statistician would rate the results as “statistically significantly” different from 10.0. What type of sampling do we carry out in production processes? Mechanical or random? Where does all this leave those who depend only on standard statistical theory for industrial applications?

Not everything in this experiment provides an example of what not to do. There is an important positive aspect to the way the control process is organized.

At first glance, it contradicts one of the ideas that Deming sometimes discusses in his seminars - and in the control process there is a division of responsibility. In fact, the contributions of each controller to the result are independent of each other; the risk of shared responsibility is reduced to the risk of consensus.

In our experiments with red beads, which we have been conducting in training seminars since 2012, we use the same procedure, without the simplifications that occurred previously.

How in funnel experiment , so in the experiment with red beads a natural question arises: what can be done to improve things? We already know the answer. Since the system in question is in a state of statistical control, real improvements can only be achieved by actually changing it. They cannot be obtained by influencing the outputs, i.e., the results of the system's operation: influencing the outputs is only suitable in the presence of special causes of variations. Influencing the results is exactly what rules 2, 3 and 4 in the funnel experiment are aimed at, and all the emotional exclamations of the master in this experiment are also aimed at.

Influencing a system to eliminate common causes of variation is usually a more difficult task than acting to eliminate special causes. So, in funnel experiment the funnel itself can be lowered or a softer cloth can be used to cover the table to dampen some of the movement of the ball after it falls. In the red bead experiment, somehow the proportion of red beads in the box must be reduced - by introducing improvements in upstream stages of the manufacturing process or in the supply of raw materials, or both.

Deming refers to the red bead experiment as "extremely simple." This is true. However, as in the case funnel experiment , the ideas conveyed in this case turn out to be not so simple at all.

Video 2. Edwards Deming: Lessons from the experiment with red beads (E. Deming: Lessons Of The Red Beads Experiment).

Below are links to two big films. Watch them at the link in the video picture directly on YouTube:

Video 3. Dr. Deming's Red Bead Experiment.

Video 4. Edwards Deming: Lessons From the Red Beads Experiment (E. Deming: Lessons Of The Red Beads Experiment)

P.S.

Sergey P. Grigoryev: Conducting training seminars, demonstrating experiments that E. Deming demonstrated at his four-day seminars, I am faced with a gap between the knowledge acquired during the training period and the subsequent application of Edwards Deming’s theory of systems management in practice by management. I see one of the main reasons for this circumstance as the unpreparedness of many managers for a full-scale change in management style, and without this transformation is impossible.

In his article [14] "THE DEMING DIMENSION: Management for a Better Future", Henry Neave estimates that approximately a quarter of a million people attended Edwards Deming's famous four-day seminars between 1980 and 1993. . This article presents an excerpt from an interview with Edwards Deming to The Washington Post conducted in 1984, which we publish below:

"You have been very successful in attracting people to these seminars. Isn't that encouraging to you?"

"I don't know why that should be encouraging. I want to see what they're going to do. It'll take years."