Technical knockout of competitors (quality => productivity + sales growth). How new knowledge can be transformed into a company's competitive advantage

Material prepared by: Scientific Director of the AQT Center Sergey P. Grigoryev .

Free access to articles does not in any way diminish the value of the materials contained in them.

A practical case about the transition of competition to a new level of thinking. Or how a statistical assessment of the quality parameters of an auto components supplier's products led it to a significant increase in sales and profits in the shortest possible time.

The approach used in this case can be used in any systems for supplying materials and providing services, according to any quality indicators demanded by buyers and customers. If you cannot use it due to the insufficient quality of your products and/or services, you can be sure that your competitors will use it sooner or later.

Technical knockout is a situation in a boxing match in which one of the boxers is unable to continue the fight while still on his feet and conscious.

Preface

The head of a company that supplied camshaft bearings (hereinafter referred to as the Supplier) to one of the largest automobile plants in Russia (hereinafter referred to as the Buyer) asked me to analyze the output of the characteristics of the supplied bearings that were critical for his Buyer.

Content

We collected data on this characteristic and used it to construct control charts of mean values and ranges of subgroups.

The Supplier's process has demonstrated a reasonable degree of statistical control (stability), and therefore uniformity of output and a high degree of predictability of future process performance, unless the process gets out of control. By the way, the best tool for receiving signals about a process going out of control are Shewhart control charts.

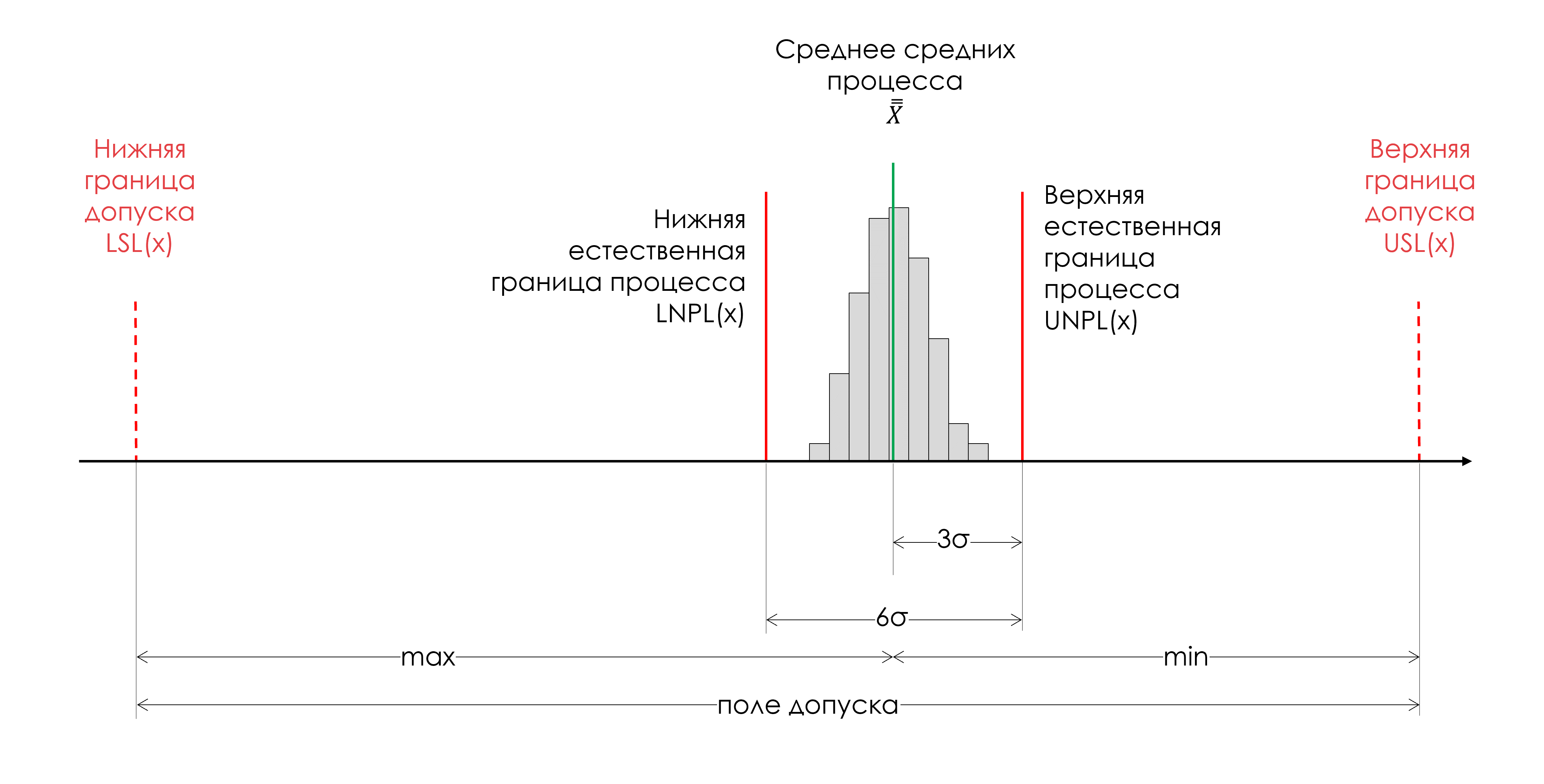

Actual reproducibility indices C calculated using Natural Process Limit (NPL) p (process living space) and C pk (centeredness of the process) relative to the Buyer’s tolerance range were: C p =5.0; C pk =4.1. See Figure 1 and Figure 2.

Figure 1. Distribution histogram of a key quality characteristic of a bearing supplier.

Figure 2. Calculation of actual process reproducibility indices (Cp, Cpk) of a key quality characteristic of a bearing supplier.

This completely satisfied the Supplier. And indeed, for production, these are very good indicators, even at the global level.

Previously, the Supplier was only interested in the fact that the quality of its products 100% met the requirements of the Buyer's specifications and that it did not produce defective products at all. Despite this, I suggested that he continue to improve the process by adjusting his average (centering - increasing the value of C pk to a value close to C p ) at the nominal value of the specification field, this is usually an easy task to solve.

I made a few recommendations and production easily centered the process at par within 1 day. Another recommendation was not to stop there and, if possible, continue to improve the process, reducing its natural scatter 6σ=UNPL(x)-LNPL(x).

The most interesting thing is that such process characteristics provide the Supplier with large unrealized opportunities. I recommended contacting all buyers of its products with a proposal to tighten specification requirements for suppliers of the same products, which will create serious obstacles for its competitors, and the Supplier itself will be able to increase supply volumes by replacing volumes supplied by competitors.

Buyer's interest in revising tolerance limits:

1. Increasing the overall reliability and quality of assembly involving the Supplier’s bearings by reducing the variability of key quality characteristics.

2. Simultaneous reduction in the cost of the Buyer’s products due to the benefits of switching to working with one supplier. See article: Transformation and continuous improvement of the procurement system .

The principle of such cooperation between the Supplier and the Buyer is based not on attempts to get into each other’s pockets, but on truly mutually beneficial cooperation when everyone wins.

If competitors, until they improve their operations, are prepared to reject their products and supply only those within a narrowed tolerance range, this will put them in a position where they will have to compensate for the losses from the production of defective products at the cost of supplying other customers and/or work, taking over serious losses, reducing expenses important for survival. This will remain so until competitors improve the quality of their products. But for this, they will need a lot: new knowledge and time.

Before we met, not a single salesperson or sales manager of the Supplier's company knew how to use the advantages at their disposal. And how could they know about this? Often the buyer's procurement team is not aware of their own company's needs at this level of thinking. Remember Deming's chain reaction?

Edwards Deming drew the chain reaction on the blackboard during all his meetings with top Japanese management since 1950. As soon as the Japanese management realized the meaning of this chain reaction, all residents of the country, starting from 1950, have found a common goal, and its name is quality.

Improve quality

Costs will be reduced due to fewer errors, rework and delays, as well as better use of machine time and materials.

Productivity will increase

Capture the market by offering better quality at a lower price

Stay in business

Save and increase the number of jobs

It is important to focus not only on key quality characteristics in accordance with the requirements of the Buyer, but also on the constant study of the needs of your customers, often even formalized by them. What does the Buyer really need?

"The consumer is the most important link in the production line. If no one buys our products, we will have to close the plant. You can achieve 100% success within the production and, in the end, go bankrupt."

Rice. No defects and no work.

Figure 3. No defects and no work. Source: [2] Edwards Deming, “Overcoming the Crisis.”

![There are no defects and there is work. Source: [2] Edwards Deming, "Overcoming the Crisis"](https://advanced-quality-tools.ru/images/articles/no_defects_will_work.png)

Figure 4. There are no defects and there is work. Source: [2] Edwards Deming, “Overcoming the Crisis.”

The Supplier's competitors quietly rested on their laurels for a long time; they were satisfied that the products fell within the Buyer's specification (tolerance) limits. They did not think about the possibility of a sharp decline in demand for their products due to the transition of competition to a new level of thinking. Why getting into the tolerance zone is not enough, see the material on Taguchi quality loss functions .

"But what does the consumer need? How can we be useful to him? What does he think he needs? Will he be able to pay for it? No one knows all the answers. Fortunately, good management does not need to demonstrate the miracles of awareness "The imperative of studying the needs of consumers and caring for the products produced have been the central doctrines of quality that have been taught to Japanese management since 1950.

The main principle here is that the goal of consumer research is to understand his needs and requirements and, on this basis, develop goods and services that can improve the buyer’s quality of life in the future.”

Important

I am sure, having understood the essence of this case, many will be able to give many examples of similar technical knockouts of competitors on a global scale.

Examples include the expansion of Japanese cars and household appliances into the American market in the early 1980s. For American business it was like a bolt from the blue.

Another example is the expansion of the young American company SpaceX, USA, into the space cargo transportation market, offering high launch reliability and the lowest prices for these services. Transportation of cargo and astronauts by SpaceX delivery vehicles as part of the NASA Commercial Orbital Transportation Services program to the ISS is already a reality. Let me remind you that SpaceX was founded in 2002 by Elon Musk.

In April 2019, I spoke at a specially organized meeting at Roscosmos with a two-hour report. The meeting was attended by: Deputy General Director of Roscosmos for rocketry, operation of ground-based space infrastructure, quality assurance and reliability, quality directors of the following state corporation enterprises: FSUE TsNIIMash, State Scientific Center FSUE "Keldysh Center", FSUE "NPO Tekhnomash", JSC "RCC" Progress", JSC NPO Lavochkina, PJSC RSC Energia, FSUE TsENKI, JSC GKNPTs im. M.V. Khrunichev." The report contained an assessment of the current state of affairs in the field of quality management at Roscosmos enterprises and demonstrated their unrealized potential. The materials of the report indicated that all rocket-building corporations in the world competing with Roscosmos have long been working to curb variability and are in search of a better system for organizing the work of people in their companies. I proposed the necessary specific measures to transform the management system in state corporations and systematically work with the quality of both our own production and throughout the supply chain of components using the presented methods and tools.

Very often I hear from top management that they are primarily interested in sales growth, and quality, somewhere in second place. Surprisingly, they forget that sales volume and market share are a consequence, not a cause. Do you need proof of cause and effect? See the materials below.

"The concept of 'fine-tuning on target with minimal variance' has defined world-class quality for the last thirty years! And the sooner you make this principle the rule of your life, the faster you will become competitive!"

Many companies have understood and adopted the concept of world class quality as succinctly formalized by Donald Wheeler, here are some examples:

Figure 5. Renault F-1 racing car.

“We ended up working with ultra-low viscosity fluids, much lower than any other product the Renault F1 team had used before, combined with smart technology in the additive systems. By upgrading their bearing system to tighter tolerances, they were able to reduce friction to a level where the engine could go a little further, run a little more."

Note!

In order for Castrol to be able to use ultra-low viscosity grease, the bearing manufacturer had to achieve lower tolerance production of bearings (due to the retention of ultra-low viscosity grease in the bearing). This once again confirms that significant innovation can only be achieved through the cooperation of all parties involved, as Edwards Deming constantly reminded, speaking about the need to expand the boundaries of the system for its better optimization.