Operational definition. Edwards Deming

"According to many industrialists, nothing is more important to business than operational definitions. And nothing in manufacturing is more neglected than operational definitions."

The material was prepared by the scientific director of the AQT Center Sergey P. Grigoryev

Free access to articles does not in any way diminish the value of the materials contained in them.

In many companies in the service, trade and manufacturing sectors, there is often no documented description of certain problem procedures that are unambiguous for all company employees to understand - operational definitions; this only increases variability in the system. There is an assumption that the procedures are completely defined and everyone follows them. How exactly are they followed? Which version of the retelling from one employee to another corresponds to the actions of the employees (as in the game of broken phone)?

It's amazing how many years it will take humanity to accept new knowledge. Another 350 years?! Compare quotes from Rene Descartes and Edwards Deming:

"People would get rid of half their troubles if they could agree on the meaning of words."

"Words have no meaning unless they can be translated into actions that everyone agrees on. An operational definition makes it possible to convey unambiguous meaning through concepts."

Edwards Deming and Walter Shewhart regarded the work on creating operational definitions as highly important and placed their importance on a par with the theory of variation and control charts. After all, the use of operational definitions has a direct bearing on reducing variability.

"Operational definitions are definitions that a reasonable person can agree to and use in practice. Operational definitions are not open to interpretation or ambiguity - on the contrary, they themselves interpret, interpret."

Deming often asked his students, “What is ‘pure’? But we should know this if our job is to wipe tables.” Does this mean the table is clean enough to either dine on, use as a counter, or operate on a patient? What is satisfactory? Satisfactory for what? Satisfactory for whom? What test procedure should we use?

"Operational definitions are the language of business. The operational definition of concepts such as “safe”, “round”, “reliable”, or any other qualitative definitions should be equally understandable for both the seller and the buyer, have the same meaning yesterday and today for a production worker. For example:

1. A specific method for testing a sample of material or subassembly.

2. Criterion (or criteria) for making a decision.

3. Decision: yes or no, object or material, meets or does not meet the criterion(s).

"The manufacturing professional has other reasons for concern. He knows that quality requirements, including conditions of fixed accuracy and precision, may be included in the contract and that the uncertainty of the meaning of any term used in establishing tolerance, including "accuracy" and "reproducibility "can lead to mutual misunderstanding and even have legal consequences. Consequently, the practitioner tries to establish as precisely defined and operational terms as makes sense."

The following is an excerpt from Edwards Deming's book Out of the Crisis. [2] - W. Edwards Deming, “Out of the Crisis: A New Paradigm for Managing People, Systems and Processes” / “Out of the Crisis”, W. Edwards Deming - M.: Alpina Publisher, 2017. Scientific editors Yu. Rubanik, Yu. Adler, V. Shper. You can purchase the book from the publisher Alpina Publisher .

Everyone thinks they know what pollution is until they try to explain it to someone else.

An operational definition of river pollution, soil pollution, and street pollution is required. These phrases have no meaning unless they are defined statistically. For example, it is not enough to say that air containing 100 parts per million of carbon monoxide is dangerous. We need to be more specific:

a) a greater quantity is dangerous if present at any time, or

b) this or a greater amount is dangerous if it is present in the air during a work shift. And how should this concentration be measured?

Does the pollution mean that (for example) carbon monoxide at this concentration will make you sick after three breaths, or if you inhale it continuously for five days? And in any case, how will this influence be detected? Which procedure will detect carbon monoxide?

How to diagnose or what is the criterion for poisoning? In people? In animals? If human ecology is to be studied, how will people be selected? How many of them will be needed? How many people in the sample must meet the criterion for carbon monoxide poisoning before the air can be declared unsafe for a few breaths or for continuous inhalation? The same questions apply to animal experiments.

Even the adjective “red” has no meaning for business purposes unless it is operationally defined in terms of tests and criteria (especially important in the printing industry - note by S. Grigoryev). “Clean” has one meaning for plates, knives and forks in a restaurant and another in the production of computer hard drives or transistors.

A businessman or civil servant cannot afford to be superficial in understanding the technical specifications (specifications) for products, medicines, and production standards.

What is the meaning of the standard that butter that goes on sale must have 80% milk fat? Does this mean requiring 80 percent or more milk fat in every pound of butter you buy? Or does it mean 80% on average? What would you mean by 80% milk fat on average? Average of all your oil purchases throughout the year? Did you mean the average production of all oil for the year or the purchases made by you or others in a particular location? How many pounds would you check to calculate the average? How would you select oil for verification testing? Would you be concerned about the pound-to-pound variation in milk fat content?

Photo: Butter, 80% fat. What is the operational definition of this amount of fat in butter?

Obviously, any attempt to define operationally what 80% milk fat is requires the application of statistical methods and criteria.

Again, the words “80% milk fat” are meaningless on their own.

Operational definitions are important for economy and reliability.

Without operational definitions of what is (for example) unemployment, pollution, product and device safety, effectiveness (of drugs for example), side effects, how long a dose lasts before side effects occur, all of these concepts are meaningless unless they determined statistically.

Without operational definitions, research into problems will be costly and ineffective, almost certainly leading to endless debate and controversy.

Laws passed by Congress and regulations of federal agencies are characterized by a lack of clarity in definitions and costly confusion (anyone can draw a parallel with the situation in our country - note by S. Grigoryev).

What does the 50% wool label mean? The label on the blanket reads "50% wool." What does this mean? Perhaps you don't care much about this inscription? You are much more interested in color, texture and price. However, some are concerned about what the label means. This includes the Federal Trade Commission, but what operational meaning does it make?

Let's say you told me you wanted to buy a blanket that was 50% wool, and I sold you a blanket that had one half made entirely of wool and the other half made of cotton.

This blanket, by one definition, would be 50% wool. But perhaps you prefer a different definition: you might say that 50% wool means something different to you. If so, then what? You can say that you meant that the wool would be distributed throughout the blanket. You might propose an operational definition like the following:

Cut 10 holes in the blanket with a diameter of 1 or 1.5 cm in random places. Number the cut samples from 1 to 10 and send them for examination.

The chemist will follow established procedures when performing the analysis. Ask him to write down the value of X; for the weight fraction of wool in each sample.

Calculate X Wed - average value of 10 shares of cut wool blanket samples.

The evaluation criteria we developed (technical requirements):

X Wed ≥0.50;

X Max -X min ≤0.02

If the sample does not meet any of the criteria, the blanket does not meet your specifications.

Drawing. The evaluation criteria we developed (operational definition, technical requirements) are 50% wool in a blanket.

Conclusion: This blanket does not meet our requirements.

Either of the above two definitions of 50% wool is neither true nor false. You have the right and responsibility to set a definition that suits your purposes. Later, you may have a different goal and a new definition. There is no true value for the percentage of wool in a blanket. However, you can get a number by completing a certain test. So far we have been talking about a single blanket. Now comes the problem of a batch of blankets. Perhaps you are purchasing blankets for a hospital or for the army. Here we come across a fundamental difference: one-time purchase versus ongoing purchases.

You might set out that for every 10kg of pure wool a manufacturer should use 10kg of pure cotton. This would be one possible definition of 50% wool, neither right nor wrong, but satisfying your purposes.

Drawing. Triangle of operationality of definition (criteria).

“The meaning of any instruction, given norms, instruction, statement or rule, a message conveyed to another person, is determined not at all by what its author had in mind, but by what is obtained as a result of its use.”

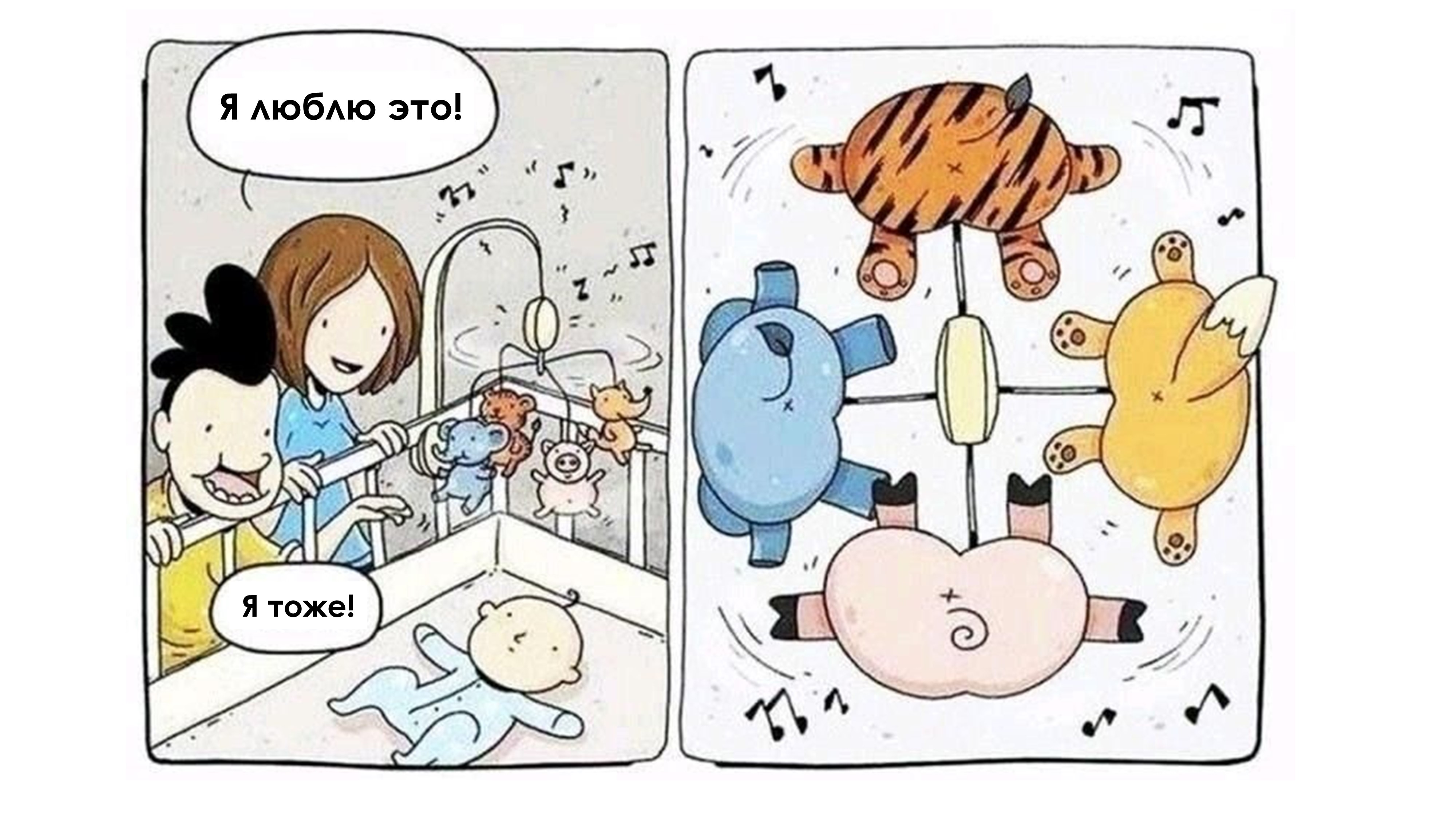

Drawing. What does the child see as a result?

An example of neglecting the operationality of a definition

Article: "Example of visualization: board with sling rejection samples", Source: up-pro.ru

At the metal finishing and finished product shipment area of section rolling shop No. 1, a board with sling rejection samples is placed. On it you can see and even check by touch what happened to the rope - squeezing, delamination, bending.

Drawing. Board with sling rejection samples

The initiator of the placement of visual information was the site foreman. He submitted the proposal through the Idea Factory and implemented it together with a colleague. Now everyone here knows what a sling that is out of service looks like.

Lifting work is potentially dangerous. Crane operators and slingers have to take many nuances into account. The main safety requirement is to check the equipment before each use. It is unacceptable to use damaged slings, as this can lead to accidents.

As the site foreman explained, of his 48 subordinates, approximately half have the related profession of slinger. Therefore, it was decided to set up a stand with a visual reminder of which ropes should no longer be used during loading and unloading. A board with samples of defective slings appeared in November last year.

“Until now, we have had many questions in the work of crane operators and slingers about the correct rejection of slings, especially metal ones, which are used most often,” says the head of the metal finishing and finished product shipment section of SWP No. 1. “There are a number of standards and requirements for them and relied on the authors of the project, who over a certain period of time collected samples of defective ropes and compiled visual information on the board.

Our comment

A beautiful stand, but unfortunately, it does not provide a clear operational definition of when a sling should be rejected.

I am sure that this stand only reduced the number of voiced questions from slingers, voiced but not raised. Yes, asking such questions will now be awkward (shameful) for them - after all, now “only a stupid person will not be able to figure it out.”

Let's try to figure it out?!

For example, the knot must be tightened or not. How to define operationally what a “node” is? How to measure "tightness"?

How many strands of wire should be extruded from a strand? Is it one to one on the sample or is one thread enough?

What is extrusion? Is it any change in the shape of the thread or a loop, wave, etc.? If the size of this “extrusion” is also important, then how to measure it? If this extrusion can be measured, what are the criteria for deciding whether to reject or not?

These questions are not for the site foreman. How does he know about the requirements for the operationality of definitions?! These questions should be asked to the company's management.

"There is no substitute for knowledge. But the prospect of using knowledge is scary."