Edwards Deming. Deming's Deadly Diseases and Obstacles to management change

"The Fourteen Points constitute a theory of management, their application should transform the Western style of management. The following are some of the "obstacles" standing in the way of transformation. All of them are of a serious nature. Unfortunately, the treatment of some of these "diseases" (for example, the fear of being displaced or the interest of business owners only in short-term profits) requires a complete revision of the Western style of management. “Deadly diseases” are the problem of almost all large American companies."

Article source: [1] - Henry R. Neave, "The Organization as a System: Edwards Deming's Principles for Building a Sustainable Business." / "The Deming Dimension. Henry R. Neave"; Per. from English - M.: Alpina Publisher, 2017. Scientific editors: Y. Adler, Y. Rubanik, V. Shper. You can purchase the book from the publisher Alpina Publisher .

Material prepared by: Scientific Director of the AQT Center Sergey P. Grigoryev

Free access to articles does not in any way diminish the value of the materials contained in them.

To simultaneously translate English-language videos into Russian, use the new Yandex Browser feature - real-time video translation.

Deadly diseases of management on the path of transformation (Deming's Diseases to transformation)

In 1984, Dr. Deming foresaw the current economic crisis and its cause by speaking of the “deadly diseases” that lay at the heart of the problem.

1. Lack of consistency

The big problem in America is a lack of consistency in the intention to stay in business, in planning for the future production of those goods and services that will help consumers live better financially (and therefore will be in demand), and will also help maintain jobs.

Continuous process improvements will increase the quality and reproducibility of goods and services and reduce costs. Shareholders who live on dividends from them are more interested in future dividends, and not just in their current value. So create conditions for them to expect dividends in three years, in five, eight years - in as many years as they wish!

2. Immediate benefit

Thinking limited by the desire for short-term gain is incompatible with purposeful business management based on development prospects.

Banks could help support forward planning and thus protect the funds entrusted to them. And yet, for them, a statement taken from life by an American banker is typical: “Jim, there is no time now to talk about quality and the future. Now is the time to cut costs, close factories and reduce wage costs.”

The desire for quarterly dividends and short-term benefits destroys the consistency of goals in the pursuit of excellence.

3. Personnel certification and ranking systems

Personnel certification and ranking systems, assessment of personal contribution, ranking by importance, bonus systems, piecework wages have a destructive effect.

Management by objectives is just as evil, since a more appropriate name for it would be “management by fear.” The results of this practice are as follows:

“Myopic” thinking develops, rivalry, intrigue and fears are nurtured, long-term planning is destroyed, and team spirit is destroyed.

Some people experience bitterness, others despair, and others experience depression that causes them to become incapacitated within weeks of receiving a performance review; Moreover, they are not able to understand what their fault is.

All of the methods mentioned are unfair because they attribute differences to people in groups that may be entirely due to the system in which they work.

"Annual performance reviews have permeated and become popular in organizations because they don't require anyone to solve people problems. It's much easier to rank those people by focusing on outputs. The idea of performance reviews is seductive. The sound of the words sparks the imagination: pay for what you get what you pay for; motivate people to give their best for their own benefit. The effect is completely opposite to what everyone promises or tries to do. advantageous for its own survival. The organization as a whole loses."

4. Managers jumping from place to place

The turnover of management personnel causes instability, leads to the fact that decisions are made by people who do not know this particular matter, and, thus, blindly copy the experience previously gained elsewhere. However, this experience does not always fully correspond to new conditions.

It takes time to truly become part of an organization, to become familiar with its processes, problems, employees and customers. Experience gained elsewhere is valuable only when the problems of the activity are understood sufficiently to evaluate the suitability of that experience. Most American companies are managed based on quarterly dividends. The President is appointed by the Board of Directors specifically to achieve this goal. He reaches it, sweeping away and destroying everything in his path, and then sets off to destroy another company.

5. Using only quantitative criteria

No one can succeed using only quantitative criteria. Of course, quantitative indicators are important: the current account requires constant monitoring, salaries must also be paid to staff and payments to suppliers must be made. But those who manage their company based only on hard numbers will soon be left without numbers and without a company.

Anyone can inflate numerical indicators at the end of the quarter: send consumers all produced products, regardless of quality, or take them into account as shipped and, accordingly, show their cost among expected receipts; cut costs on research, education, and training; fire employees involved in quality management, fighting to reduce the payroll.

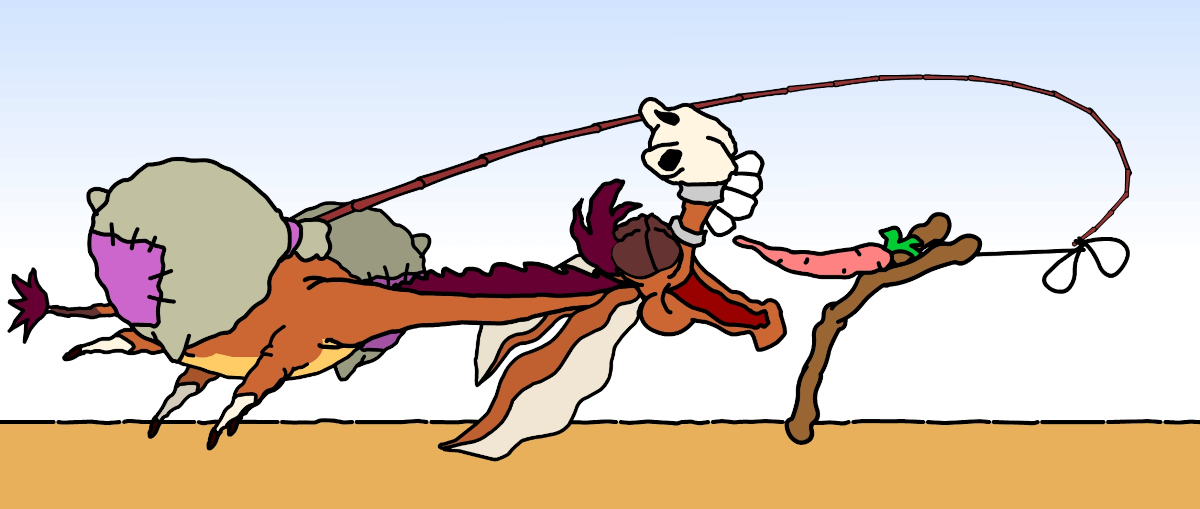

Rice. Manipulation of numerical targets.

S. Grigoryev: An example that is popular with one (winning) half of the world scientific community and hated by the other (losing) is a destructive quantitative indicator "Hirsch index (h-index)" , which was designed to provide a more adequate assessment of a researcher's scientific productivity.

However, we should not forget the words of Lloyd Nelson that the quantities most important for management are unknown and quantifiable.

In addition to “deadly diseases,” there is also a whole parade of obstacles. Some of them are as dangerous as "diseases", but most of them are easier to eliminate (easier, but not easy).

Deming's obstacles to transformation

Instant Pudding Hopes

“Come, spend a day with us and do for us what you did for Japan.”

The assumption is that by solving current problems, introducing automation, fixtures and new machines, we will transform industry.

Quality cannot be bought with money.

Searching for examples

Examples teach nothing unless they are examined through theory. Many people are simply looking for examples to copy.

See article about the pointlessness of searching for examples .

"We have other problems."

Maybe, but the principles that help solve them are universal.

Outdated approaches in business schools

In business schools, students are taught that there is such a profession as “manager” and that they are already quite ready to take leadership positions. This is a cruel prank, a joke. They only teach how to take a position in a company, but not how to manage it.

Insufficient training in statistical methods in industry

Confidence intervals, significance tests, etc. will at best tell us what we already have. To suggest that they were obtained for prediction and planning would be deceptive and misleading.

Using Military Standard 105D and Other Tables to Conduct Acceptance Sampling Inspection

These standards start from the premise that there is an “acceptable level of quality” and thus negate the need for improvement.

"Moreover, compliance with the 105D standard (and its analogues in GOST R - see list) does not take into account the requirement to minimize the total average cost of control and losses at the enterprise, and if the degree of statistical controllability of the quality of incoming materials is high, sampling control would not provide ideas about the rest of the controlled lot, due to the lack of signs of correlation between them in this case."

“Our quality management department handles all of our quality issues.”

I would if I could!

“Our problems relate solely to the quality of our employees.”

A pleasant misconception. It is precisely this system that prevents employees from working fully, and it itself is under the control of managers and managers.

False start

Very much related to the implications of the aforementioned hopes for instant pudding and “we have implemented quality management.” Mass training in statistical methods, quality circles, solicitation of proposals, employee participation programs, etc. are all attempts to cut corners on the path to quality. There are no shortcuts here.

"We have implemented quality management."

For quality, it is not methods that matter, but knowledge. Methods and equipment can be implemented, knowledge and understanding cannot.

Vain hopes for computerization.

A computer can be a blessing. He could be a curse. The computer simply stores data. If you don't use them, they will remain there.

The assumption that meeting specifications is all that is needed.

Tolerance limits, technical specifications requirements - that's not all. Compliance with requirements can satisfy the consumer, nothing more. This assumption is a barrier to improvement.

The fallacy of the “zero defects” theory.

Companies went bankrupt, although they made products without errors or defects.

Rice. No defects and no work.

Inadequate testing of prototypes.

The prototype is single, its parameters are artificially close to the nominal ones. Without knowledge of variations, variability cannot be predicted.

“Anyone who comes to help us must understand everything about our business.”

Why? People who are competent in a given business know everything except how to improve it. Improvement requires a new type of knowledge. And it's up to people in companies to make these improvements by combining new knowledge with what they already have.

This list of “deadly diseases” and obstacles prepared by Edwards Deming is by no means exhaustive.

I (Sergey P. Grigoryev) will easily complement it:

"We have no quality problems. All our problems are related solely to the quality of our suppliers."

When we contact their suppliers, they tell us the same thing about their suppliers. How can products assembled from low-quality products from suppliers not have quality problems?! Why then are their consumers not satisfied with the quality?! The management of these companies simply does not know anything about their responsibility for quality.